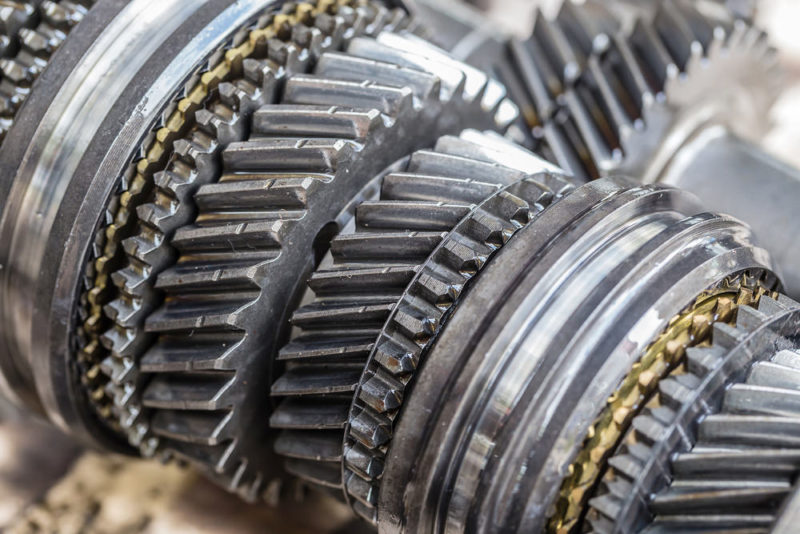

Automobile Gearboxes: How Handbook And Automated Gears Work

These supplies not only make gears stronger but in addition extra eco-friendly, addressing the stringent emission rules. Another less frequent type of automatic transmission known as a dual clutch transmission, or DCT. In a DCT, there are literally two separate clutches that management even and odd gears.

For heat treating, nitriding is used, however as a outcome of the nitrided floor is shallow, tooth grinding is not doable. The inventory gears supplied by KHK are, with exception of CP gears, largely module primarily based metric gears and are broadly used all around the world. On the opposite hand, KHK can also produce custom gears in module , CP and DP gears. Besides module as the measure of tooth dimension, there are previously talked about DP and CP . When CP is used and a pinion rotates once, the space moved turns into an integer and is handy in positioning in linear movement.

‘Geographic reach’ refers to the number of countries each patent is registered in. It displays the breadth of geographic utility meant have a peek at this site, ranging from ‘global’ to ‘local’. ‘Application diversity’ measures the variety of functions recognized for each patent.

Why Your Automotive Is Struggling To Change Gears?

They also can tackle the advanced shapes wanted in modern high effectivity gears, such as break up path planetary drives, worm gears, and inside gears, at AGMA precision levels of Q6 to Q9. In addition to design flexibility, plastics are a lot cheaper than stamped or machined metal gears. Composite materials has big requirement in the area of car, aerospace, and wear resistant applications. This research presents the synthesis of composite strengthened with SiC and Al2O3 utilizing gravity stir casting. Stir casting is the manufacturing course of that’s integrated to provide the composite materials because of its extreme bonding capacity with base materials.

Diagnostic Tool Helps Develop Profile For Induction Hardening Process

For example, workplace gear, hydraulics, small medical units, and different purposes with low load requirements. The aforementioned supplies come with the right steadiness of these properties for his or her functions. That’s why you’ll commonly see them in most gears you come throughout.

During our metallic 3D printing member webinar on May 1, greater than 25 questions were fielded by Dr. Rogers by the greater than 60 attendees. He supplied information on the biggest dimension gears that can be made utilizing laser-powder fusion. On most machines, it is 9.5 inches square; however, the biggest machines obtainable have 500mm x 800mm construct platforms, so there may be the likelihood for one thing within the realm of 15 to 17 inches in diameter. He described the accuracy for laser sintered elements is plus-or-minus about zero.1mm, however that it does range by software and system. While AM techniques have been invented greater than 30 years ago, they have been primarily thought for use to customize our environment. It has only been in recent years that these processes are being looked at and developed as a mass production expertise.